Glass machining services

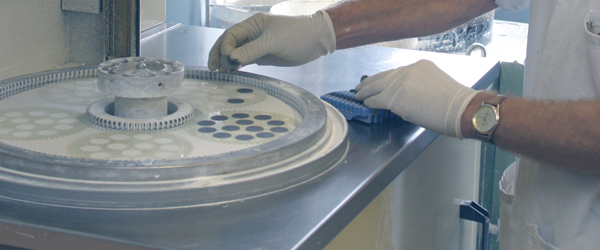

UQG Optics offers glass and optical machining services on customer materials and components. Jobs can range from simple tasks such as cutting a piece of float glass in half to more complex tasks such as cylindrically grinding quartz rods to tolerances of 0.01mm.

We can undertake precision grinding and cutting of one-off custom or stock optical components to achieve specific dimensions, as well as contract production.

Contract work is undertaken to customer-supplied components and materials.

For precise micro dicing see our precision dicing services.

Materials & Components Include:

Optical glasses, technical glasses, rod, tubes, optical components, fused silica, quartz, BK7, borosilicate, sapphire, silicon, filters, mirrors, lenses, float glass, alumina, ceramics, ferrites, macor and many more.

Machine services offered include the following:

CNC surface grinding

Reducing bulk glass surfaces to a surface finish of 50 microns. Grinding tolerance to ± 0.05.

CNC surface grinding

Reducing bulk glass surfaces to a surface finish of 50 microns. Grinding tolerance to ± 0.05.

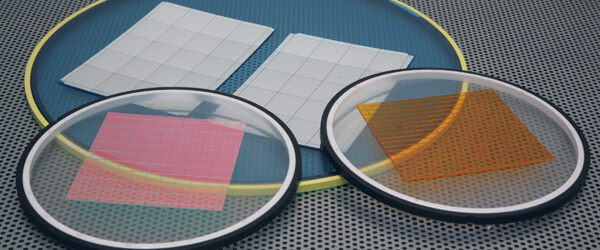

CNC (diamond) sawing

Diamond sawing squares and rectangles from sheet glasses and optical materials to a cutting depth of 100mm. Cutting tolerance to ± 0.20mm.

Annular ID sawing

Precision ID slicing of substrates, wafers and components up to 100mm diameter. Cutting tolerance to ± 0.05mm.

Cylindrical grinding

OD grinding of rods and tubes or stack edging filters. Diameters 5mm to 250mm. Grinding tolerance to ± 0.01mm.

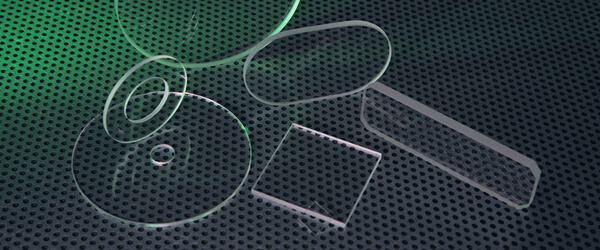

Waterjet cutting

Waterjet cutting is ideal for achieving shapes and complex designs, glass rings, and cutting technical sheets and glasses. It’s is also used to cut AR coated sheets and quartz sheet leaving a ground edge with no tooling costs. Cutting tolerance to ± 0.10mm.

Glass scribing

The slicing scribe & break process uses CNC multi- or single-blade cutting wheels and is ideal for ultra-thin glass and coated glass sheets. Additional working such as bevelling can be applied after cutting. Cutting tolerance to ± 0.1mm.

Bevelling and chamfering

Sharp edges and corners can be ground using our bevelling and chamfering process to a uniform size and angle. This is ideal to accommodate housings, for protection of assembly operators and protection of components.

Glass drilling

Diamond drilling and trepanning holes, cylinders and discs. Holes are drilled to a minimum of 2mm diameter, or for smaller sizes laser or ultrasonic drilling is recommended. Drilling tolerance to ± 0.05.

Milling

CNC milling to cut outs, strips and recesses around the edges of squares and rectangles. Grinding tolerance to ± 0.05.

Diffusing & sand blasting

Faces and surfaces can be diffused by either fine alumina or grinding grit. We offer a range of sand blasting grades ranging from from 10 microns to 100 microns.

For more information about precise micro dicing, see the Dicing Services page.