When it comes to manufacturing high-precision optical components, achieving perfection requires the perfect tools for the job. This pursuit of excellence is what drove the recent investment by UQG Optics in two of the industry’s most advanced micro dicing machines: Loadpoint and the Disco DAD 3350 Automatic Dicing Saw.

Parallel Precision Cutting

This high-speed cutting action, along with specific resin bond diamond blades designed for dicing hard, fragile materials such as glass, sapphire, and ceramics, allows for extremely exact, parallel singulation.

Both the Loadpoint and Disco have a dual-spindle design with one cutting blade positioned in a co-planar configuration. This method doubles cutting efficiency while assuring zero-degree taper or angle variation throughout the cut depth, which is crucial for many optical applications.

Advanced Tape Handling

Instead of drilling directly into the substrate, these machines use a specialist vacuum chuck to bind the workpiece to an adhesive tape coating. This revolutionary tape handling technique fully preserves the surface finish while cutting, preventing chips, cracks, scratches, and other damage.

The adhesive tape also allows for extremely thin dicing, down to 10 microns—a fraction of the thickness of human hair. Following singulation, the tape facilitates the removal and separation of individual dies or components.

High-Precision Positioning

With cut tolerances estimated in single-digit microns, achieving such remarkable accuracy necessitates incredibly fine positional control of the cutting head relative to the workpiece. The Loadpoint and Disco use high-resolution linear motor translation stages with integrated ceramic scales to achieve positioning resolutions as low as 0.1 micron.

This level of dimensional precision across all three axes enables UQG to maintain extremely tight tolerances during the dicing process, even on bigger workpieces such as entire semiconductor wafers up to 300 mm.

Intelligent Automated Control

Of course, eliminating hardware is only one aspect of the situation. Both of UQG’s latest micro dicing platforms include superior automatic dicing software and intelligent process control features.

This clever programme automatically determines the best dicing lane configuration to maximise material utilisation and part production. It also continuously checks and compensates for issues such as expected blade wear and material irregularities via real-time feed adjustment.

Most impressively, the automatic control allows for hands-free operation of whole production runs, from workpiece loading and alignment to final singulation, significantly enhancing throughput, repeatability, and overall manufacturing efficiency.

Seamless Integration, Maximum Output

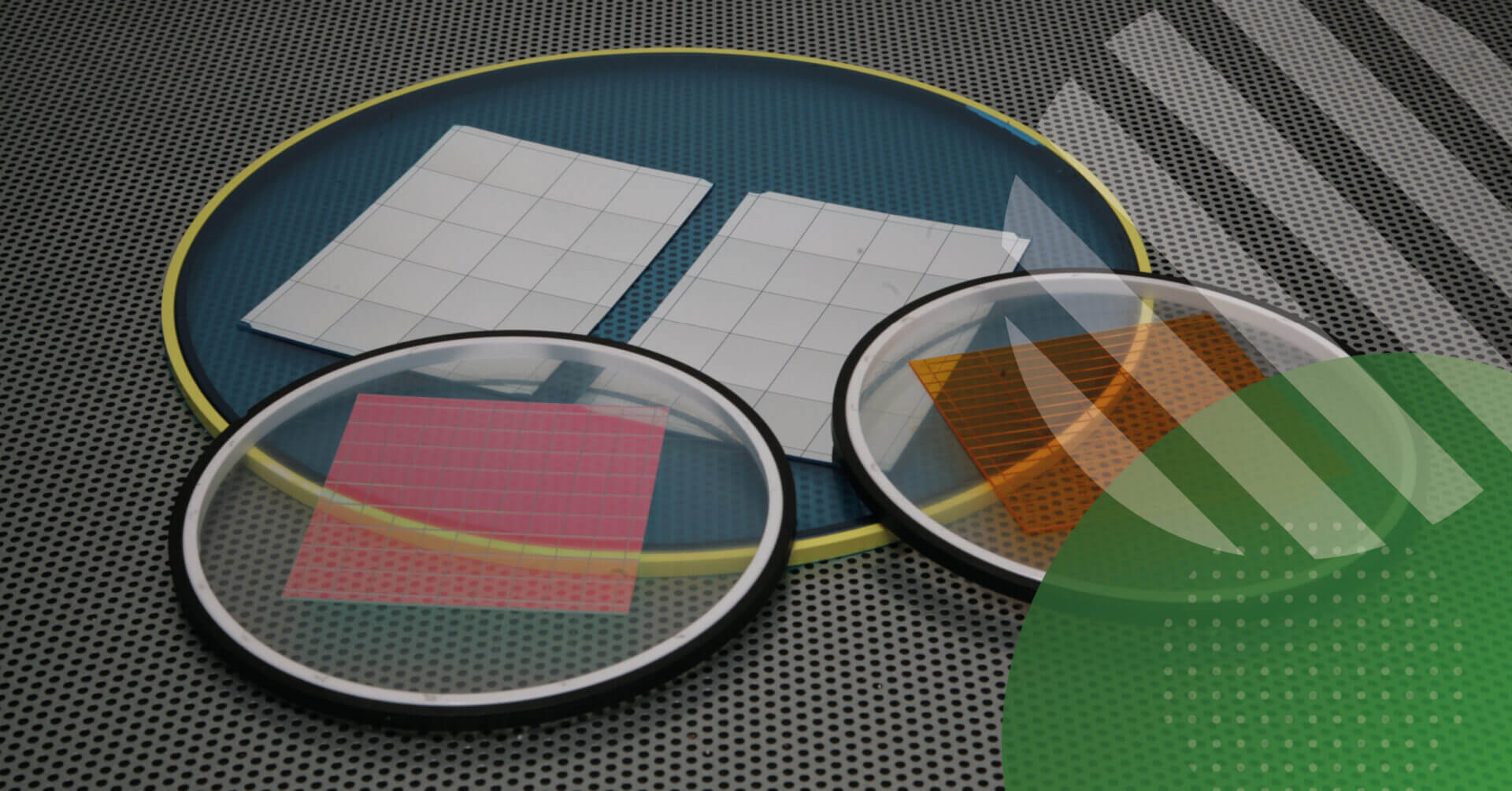

By seamlessly integrating these cutting-edge micro-dicing machines into their existing manufacturing workflows, UQG Optics has expanded its small component production capacity dramatically.

The Loadpoint and Disco can divide enormous sheets or ingots into thousands of individual dies, chips, or other micro-optical elements in a single automated cycle, with the tape method allowing for maximum material utilisation and nearly no losses.

This dicing capability, combined with extraordinarily high production tolerances and surface quality, enables UQG to produce dense microstructures, waveguide arrays, gratings, micro-lenses, and a wide range of other specialty optical components at previously unachievable scale.

The Cutting Edge of Possibility

UQG Optics’ adoption of these cutting-edge micro-dicing platforms from Loadpoint and Disco is a significant complement to their extensive range of optical fabrication technologies and machining capabilities.

UQG continues to set new benchmarks for high-precision optical component and system manufacture by combining innovative technology like this with a highly experienced team of engineers and craftspeople.

As new production techniques emerge—from breakthroughs in laser dicing to AI-controlled processes—the company remains solely focused on implementing the most recent innovations to achieve improved accuracy, quality, and throughput for their global customers.

If you’d like to find out more, contact our team or call us at 01223 420329 or email our sales team at info@uqgoptics.com.