Infrared (IR) fused quartz windows have become indispensable components in various scientific and industrial applications.

These specialised optical elements offer exceptional transmission properties in the infrared spectrum, making them crucial for precise measurements, laser systems and advanced imaging technologies.

Key Takeaways

- IR fused quartz windows offer exceptional transmission in the 260nm to 3500nm range.

- These windows feature low water content, high thermal stability and excellent chemical resistance.

- Applications include laser systems, infrared imaging and optical filter substrates.

- Innovations in production allow for customised shapes, sizes and coatings.

- IR fused quartz windows provide a cost-effective and versatile solution for various optical needs.

Manufacturing Process

High-Purity Natural Quartz

The production of IR fused quartz windows begins with high-purity natural quartz. This raw material is carefully selected to ensure minimal impurities, which is essential for the final product’s optical and physical properties.

Electrical Fusion Method

The quartz is electrically fused, a process that involves melting the material at extremely high temperatures. This method results in a homogeneous material with exceptional optical clarity and uniformity.

Key Properties

IR fused quartz windows boast several remarkable characteristics that set them apart from other optical materials:

Wide Transmission Range

These windows offer useful transmission in the infrared spectrum from 260 nm to 3500 nm, making them suitable for a broad range of applications.

Low Water Content

The manufacturing process results in an incredibly low water (OH) content, typically 5 ppm or less. This low OH content is crucial for maintaining optical clarity and reducing absorption at specific IR wavelengths.

Thermal Stability

IR fused quartz has an extremely low coefficient of thermal expansion, ensuring dimensional stability across a wide temperature range.

Chemical Resistance

The material exhibits outstanding chemical resistance and purity, making it suitable for use in harsh environments and sensitive applications.

Applications

Laser Systems

The wide transmission range and thermal stability of IR fused quartz windows make them ideal for various laser applications, from industrial cutting to scientific research.

Infrared Imaging

These windows serve as cost-effective solutions for infrared imaging systems, enabling clear transmission of IR wavelengths for thermal cameras and spectroscopic instruments.

Optical Filter Substrates

IR fused quartz windows are excellent base substrates for IR optical filter coatings, allowing for the creation of specialised optical components.

Innovations in Production and Customisation

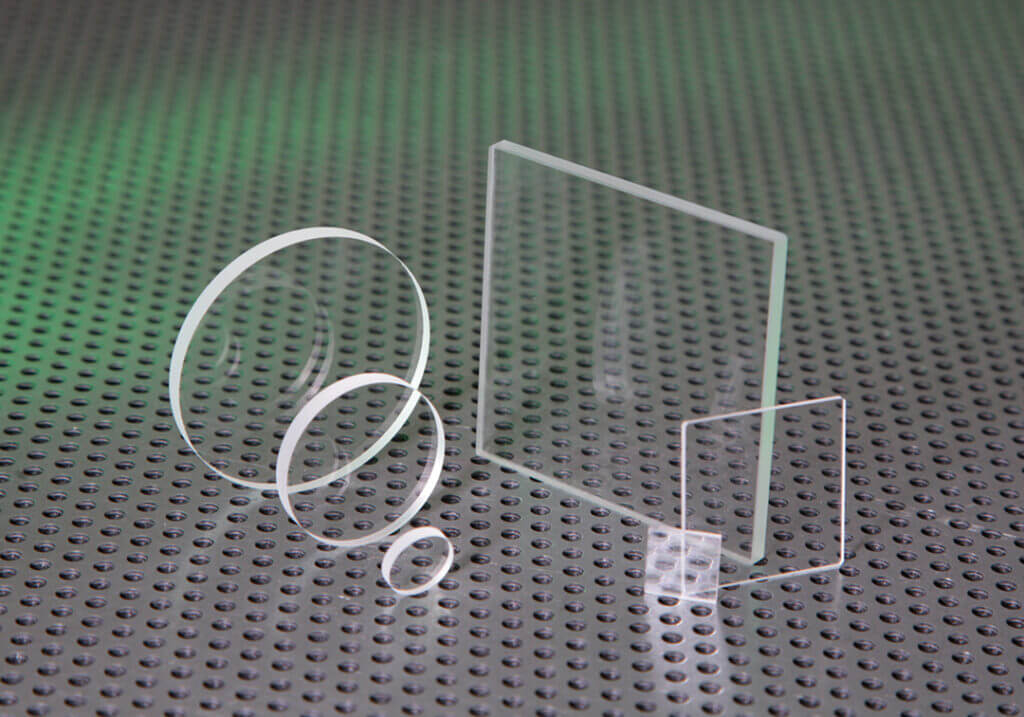

Stock and Custom Options

Manufacturers now offer a wide range of stock sizes and custom options, providing flexibility for various application requirements.

Enhanced Surface Flatness

Advancements in manufacturing techniques have led to improvements in surface flatness, crucial for maintaining optical performance.

Specialised Coatings

Innovative coatings can be applied to IR fused quartz windows, enhancing their performance for specific wavelengths or environmental conditions.

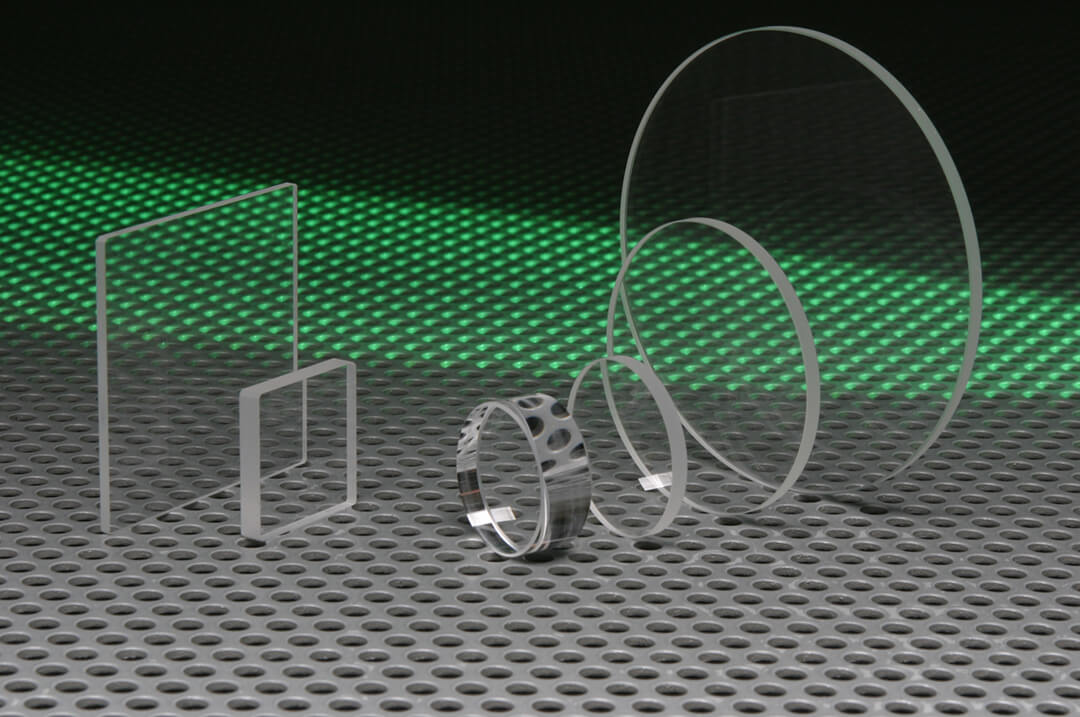

Diverse Shapes and Dimensions

Beyond traditional circular windows, manufacturers can now produce IR fused quartz windows in various shapes and dimensions to meet unique design requirements.

Advantages Over Other Materials

IR fused quartz windows offer several benefits compared to alternative materials:

– Cost-effectiveness, especially for larger sizes – Exceptional durability and resistance to environmental factors- Versatility across a wide range of applications

Future Prospects

As technology advances, IR fused quartz windows are likely to find new applications in emerging fields such as quantum optics, advanced sensing technologies and next-generation communication systems.

Why Choose Our IR Fused Quartz Windows?

When it comes to IR fused quartz windows, our company stands at the forefront of innovation and quality. With 65 years of experience in manufacturing and supplying these critical optical components, we have established ourselves as the go-to experts in the field.

Unmatched Expertise

Our team of skilled professionals possesses in-depth knowledge of IR fused quartz properties and applications. This expertise allows us to provide tailored solutions that meet the most exacting requirements of our clients across various industries.

Comprehensive Range

We pride ourselves on offering an extensive stock of IR fused quartz windows in a wide range of sizes. Moreover, our custom manufacturing capabilities enable us to produce windows with specific surface flatness, coatings, shapes, materials and dimensions to suit your unique needs.

Quality Assurance

Each IR fused quartz window we produce undergoes rigorous quality control measures, ensuring that you receive only the highest quality products that meet or exceed industry standards.

Customer-Centric Approach

We understand that each project is unique. Our dedicated team works closely with clients to understand their specific requirements and provide personalised solutions that drive success in their applications.

Get a Quote Today

Ready to elevate your optical systems with our premium IR fused quartz windows? Don’t hesitate to reach out for a quote tailored to your needs. Our team is standing by to assist you in selecting the perfect IR fused quartz windows for your project.

Contact us today to discuss your requirements and receive a comprehensive quote. Let us help you push the boundaries of what’s possible with cutting-edge IR fused quartz windows.