Fused silica and fused quartz are amongst some of the most popular optical materials. However, there can be some confusion between the two due to their similar properties, to the components, they are used for. In this article, we’ll look at the differences and similarities between fused quartz and fused silica.

Key Takeaways

- Fused Silica is a synthetic material and the purest form of glass, offering high transmission in the UV spectrum.

- Fused quartz is made from naturally occurring material in the form of crystalline quartz or silica grains. Fused quartz glass is manufactured by melting the natural quartz crystals, with the results containing more impurities than fused silica.

- Due it’s purity, fused silica can be the ideal material for applications such as items of optical equipment which rely on UV transmission.

- Despite it’s lower optical quality, fused quartz has excellent optical, electrical and thermal properties, as well as being highly resistant to corrosion.

- Both Fused silica and quartz offer low thermal expansion, high working, and melting temperatures, and are highly corrosion resistant.

What is Fused Silica?

Fused silica is a synthetic material. It is a non-crystalline silica glass and is made from either pure silicon gas or non-crystalline silica sand. Fused silica is the purest form of glass, offering high transmission in the UV spectrum.

It can be manufactured in translucent or opaque form and the purity it offers makes it the ideal material for applications such as items of optical equipment which rely on UV transmission. An example of this would be equipment which uses UV rays in order to sterilise surfaces and or/equipment for medical purposes. The purity it offers also makes fused silica the material of choice for the manufacture of semi-conductor and laboratory equipment.

What is Fused Quartz?

Unlike fused silica, fused quartz is made from naturally occurring material in the form of crystalline quartz or silica grains. Fused quartz glass is manufactured by melting the natural quartz crystals, with the results containing more impurities than fused silica.

This means that fused quartz has a lower OH content than the synthetic alternative, as well as lower optical quality and more flaws and bubbles. In most cases, fused quartz glass is transparent and, despite being inferior in quality to fused silica, can still offer excellent optical, electrical and thermal properties, as well as being highly resistant to corrosion.

The degree to which fused quartz glass contains impurities and/or naturally occurring flaws will be governed by the quality of the quartz sourced for its manufacture. Although fused quartz glass contains more flaws than fused silica, it should be noted that these flaws will not be visible to the naked eye, and only impact upon the viability of fused quartz as a material for applications with extremely high optical requirements.

Properties shared by Fused Quartz and Fused Silica

Despite their differences, fused quartz and fused silica do share some properties, such as the following:

- They both offer low thermal expansion

- They both offer excellent optical properties

- They both offer high working and melting temperatures – the maximum temperature at which both can be used is 1450°C, while both can be used for a sustained period at temperatures of 1,100°C. In both cases the softening point of the glass will be hit at roughly 1,730°C.

- They are both highly corrosion resistant – each offers acid resistance which is 150 times more than stainless-steel and 30 times more than ceramics. The only acid likely to cause any reaction in fused quartz or fused silica glass is hydrofluoric acid.

Both types of glass – fused quartz and fused silica – are widely used in sectors such as:

- Metallurgy

- Chemical and Pharmaceutical

- Construction

- Communications

- Semiconductors

- Defence/Military

- Environmental protection

Choosing between Fused Silica and Fused Quartz

When a client comes to UQG Optics with a requirement they sometimes know whether they need fused quartz or fused silica, but in other cases they may not be entirely clear. We will draw on our expertise and experience to advise as to which of the materials will be best suited to the optical component in question.

Fused silica, for example, is manufactured using a process known as flame hydrolysis. Although this offers the highest possible level of purity it is also expensive, complex and time consuming, and is only needed in those components which demand the very highest levels of optical purity.

For many applications, fused quartz glass provides sufficient levels of optical purity as well as the other shared properties detailed above, whilst being less expensive and time consuming to manufacture. For those reasons we will often recommend it to clients, particularly if they are seeking large-scale production of optical components or working to tighter budgets and deadlines.

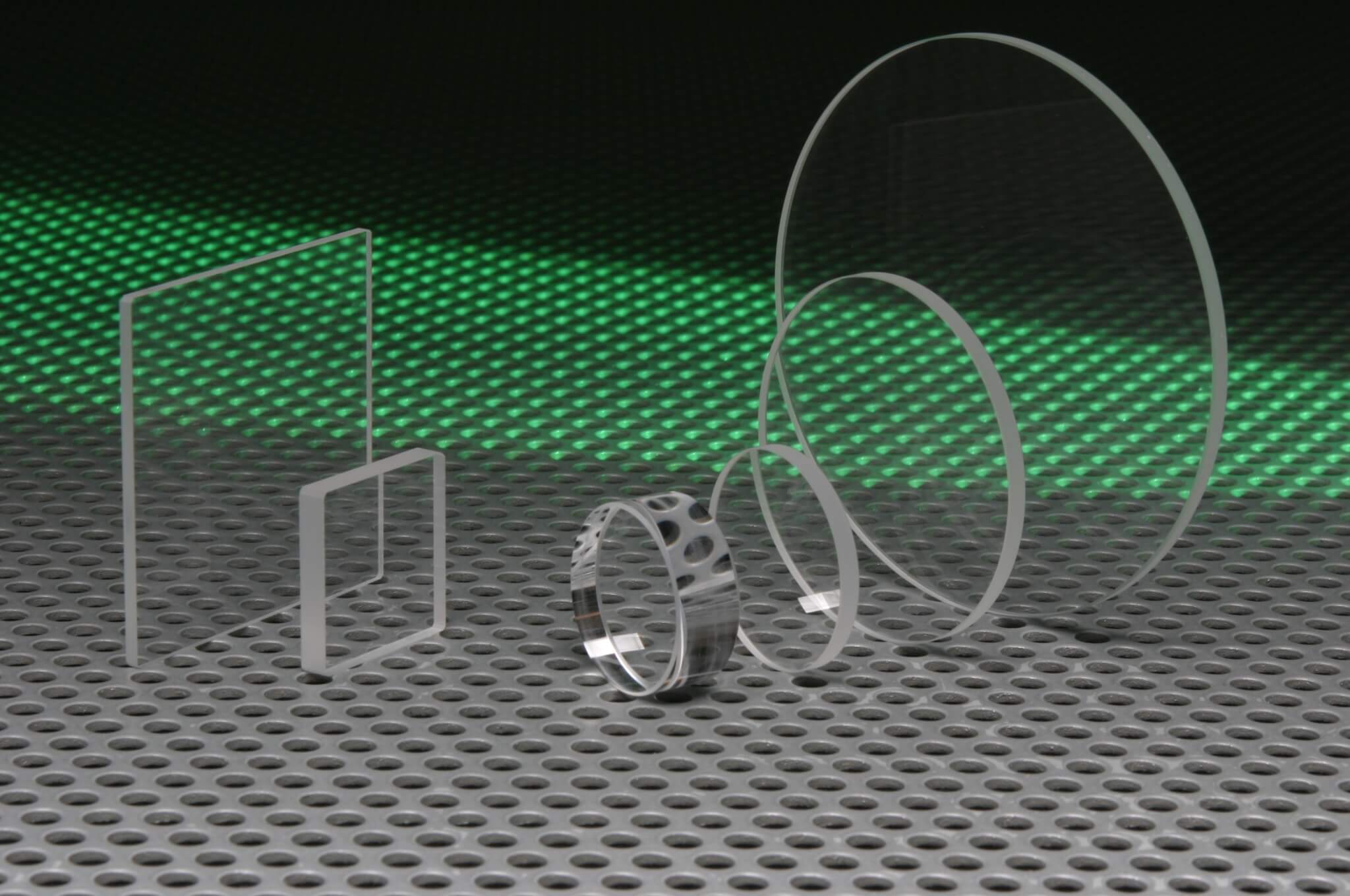

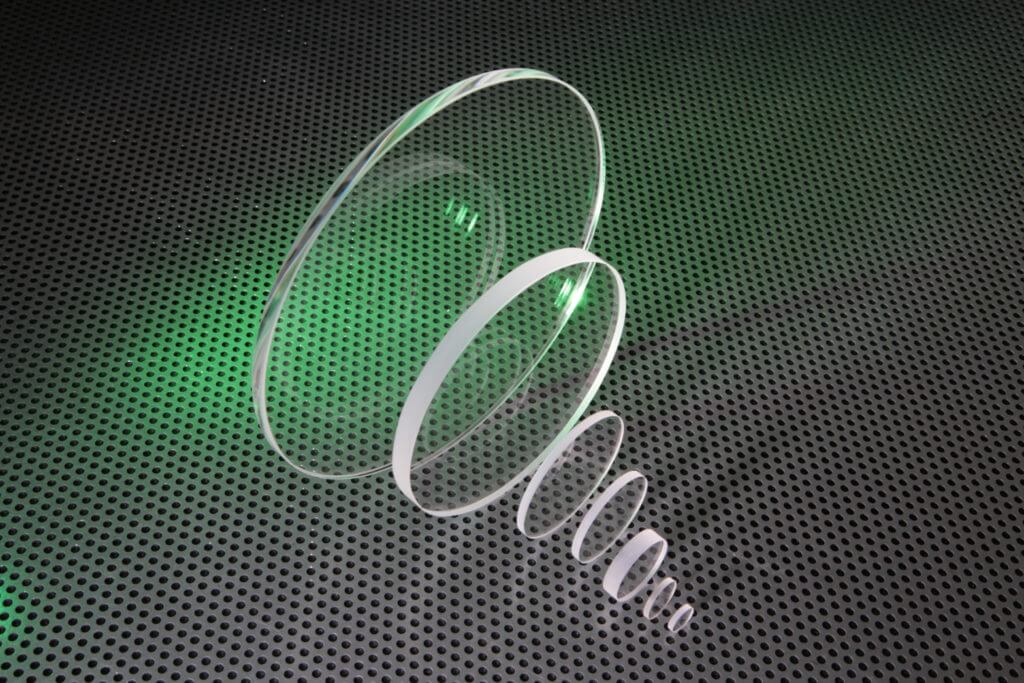

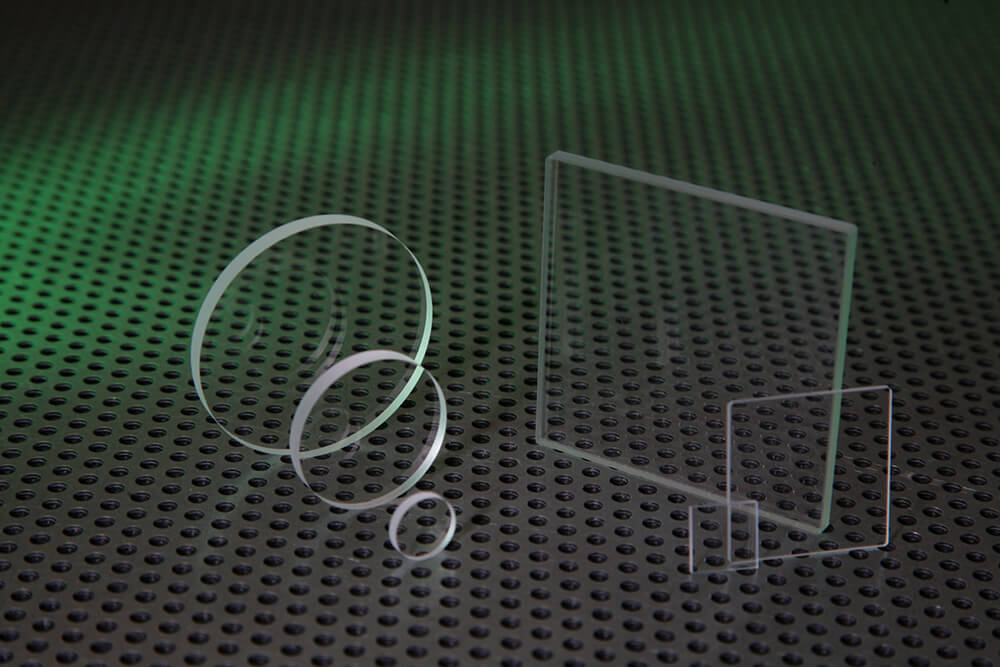

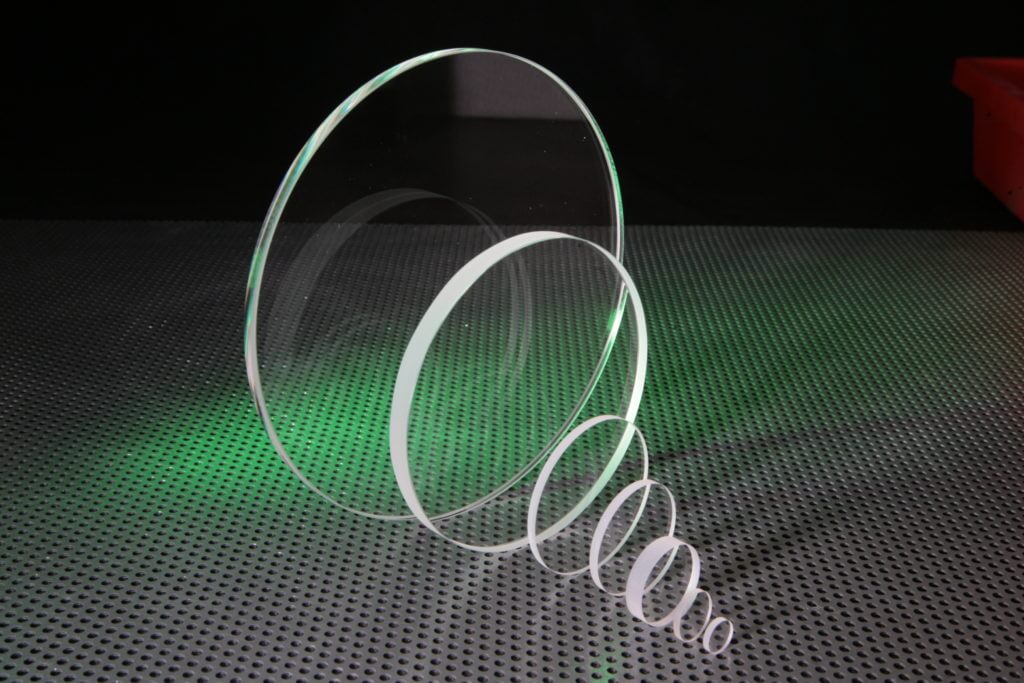

Custom and Stock Fused Quartz and Silica

If you’d like to learn more about fused silica, fused quartz and the differences between the two types of glass, or have a specific project which you need to discuss, please call us on 01223 420329 or email our sales team at info@uqgoptics.com