Sapphire windows, while not as well-known as diamonds, are quietly revolutionising industries that require high-performance optical materials. These transparent, ultra-durable components are reshaping the way we approach precision optics, from aerospace technology to advanced scientific research.

Sapphire windows have become the preferred alternative over ordinary glass due to their exceptional resistance in severe situations and superior optical clarity.

Let’s look at how this material is creating new norms in optical engineering.

The Science Behind Sapphire

Sapphire, a crystalline form of aluminium oxide (Al₂O₃), has a distinct atomic arrangement that gives it exceptional physical qualities. Unlike normal glass, which is an amorphous solid, sapphire’s densely packed crystal lattice is extremely resistant to scratches, thermal stress and pressure.

These characteristics make sapphire windows indispensable in high-performance applications where durability and clarity are critical.

Why Sapphire Stands Out

- Unmatched Hardness: Second only to diamond in hardness, sapphire resists scratches and abrasions, making it ideal for high-wear environments.

- Thermal and Chemical Resilience: Capable of withstanding extreme temperatures and exposure to corrosive chemicals, sapphire remains stable in conditions where traditional glass would degrade.

- Superior Optical Properties: Transmitting light across a broad spectrum from ultraviolet (UV) to infrared (IR), sapphire windows enable advanced imaging, laser applications and scientific instrumentation.

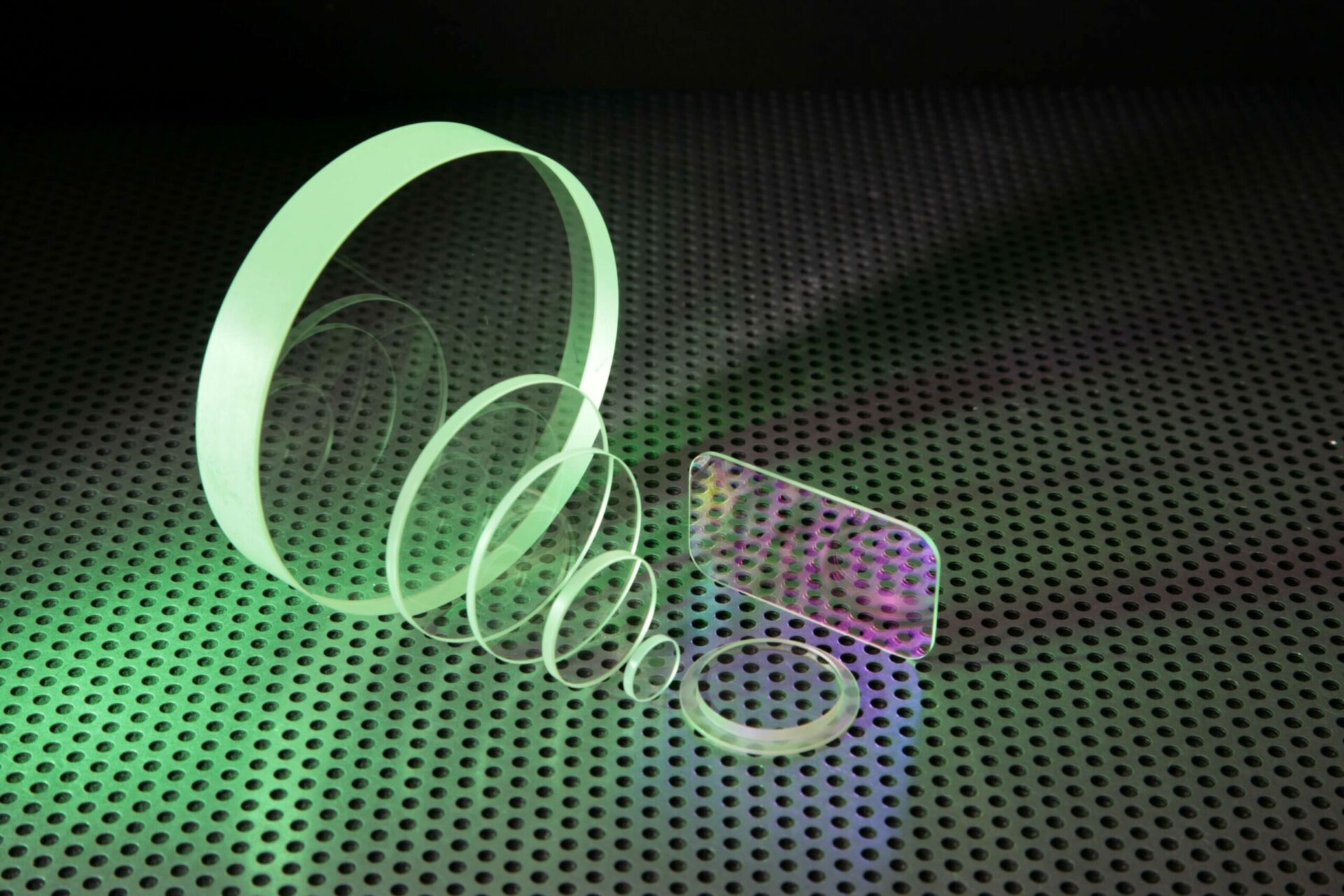

How Sapphire Windows are Manufactured

The production of high-quality sapphire windows requires sophisticated fabrication techniques to ensure optical precision and structural integrity. Key processes include:

Cutting and Shaping

Using diamond-edged tools, raw sapphire is sliced into desired dimensions before undergoing grinding and lapping.

Polishing and Coating

Advanced polishing techniques achieve an ultra-smooth surface, often followed by anti-reflective coatings to enhance optical efficiency.

Where Sapphire Windows Shine

Sapphire windows are being deployed across multiple industries, each leveraging their unique properties to push technological boundaries.

Aerospace and Defence

Sapphire windows, which can withstand tremendous pressures and temperatures, are utilised in aerospace and defence, such as in aircraft sensors, cockpit displays and missile domes to provide clarity and durability in high-stress conditions.

Medical and Scientific Equipment

Sapphire’s ability to transmit UV and IR light makes it ideal for optics in medical applications, such as imaging devices, endoscopes and high-precision laboratory instruments, where optical clarity is crucial.

Consumer Electronics

Premium manufacturers incorporate sapphire into smartphone camera lenses and display covers, taking advantage of its scratch resistance to enhance durability.

Industrial and Manufacturing Uses

Optics used in harsh manufacturing environments must be able to withstand these conditions. Sapphire windows are used to provide protection for optical sensors and laser cutting equipment, ensuring longevity and reliability.

Sapphire Windows in Extreme Environments

One of the most notable advantages of sapphire windows is their ability to work consistently in some of the harshest settings on Earth and beyond. Whether exposed to scorching heat, caustic chemicals, or high pressures, sapphire stays unyielding while other materials fail.

Deep-Sea Exploration

Underwater drones, submarines and scientific gear rely on sapphire windows to survive the extreme pressures of the ocean bottom. Traditional glass would fracture in these temperatures, but sapphire’s extraordinary mechanical strength provides optical clarity and durability for deep-sea photography and laser communication systems.

Space and Satellite Applications

In space, materials must withstand significant temperature variations, high radiation levels and micrometeoroid impacts. Sapphire’s resistance to thermal expansion and optical stability in vacuum environments make it an ideal material for satellite lenses, space telescopes and astronaut helmet visors.

High-Temperature Industrial Settings

Windows that can withstand exposure to heat and chemicals are necessary for manufacturing settings that involve molten metals, strong radiation, or powerful lasers. Sapphire is essential for high-energy physics experiments, furnace observation windows and semiconductor production because of its capacity to maintain optical clarity while fending off thermal shock.

Emerging Innovations in Sapphire Technology

As technology improves, sapphire windows’ role evolves. Researchers are looking into new fabrication processes to lower production costs and improve optical performance. Possible potential applications include:

- Quantum Computing: Sapphire’s high optical clarity makes it a candidate for quantum optics and advanced computing applications.

- Photonics and Optical Communication: Its stability and transmission properties are driving innovations in high-speed data transfer technologies.

- Space Exploration: Sapphire’s durability makes it an excellent choice for deep-space missions, where optical instruments must endure extreme conditions.

Final thoughts

Sapphire windows are no longer a specialist material; they are becoming increasingly important to the future of optical engineering. Their distinct mix of strength, thermal stability and optical precision guarantees their continuous use in industries seeking high-performance solutions.

To find out more about Sapphire Windows and Plates from UQG Optics, or any of our other optical components, call us on 01223 420329 or email our sales team at info@uqgoptics.com