Sapphire windows and plates are flat optical components which are placed in a range of devices and systems with the purpose of transmitting the specific wavelength of light required by the application in question. Once in place, the window or plate also provides protection for other parts of the optical system, guarding against the effects of environmental aspects and application specific factors such as temperature and pressure.

The design and manufacture of the optical window or plate is undertaken with the aim of maximising transmission and reducing reflection. Sapphire substrate can have additional optical coatings applied to deliver optical effects such as protection from x-rays and the transmission of light ranging from deep ultra-violet to far infra-red.

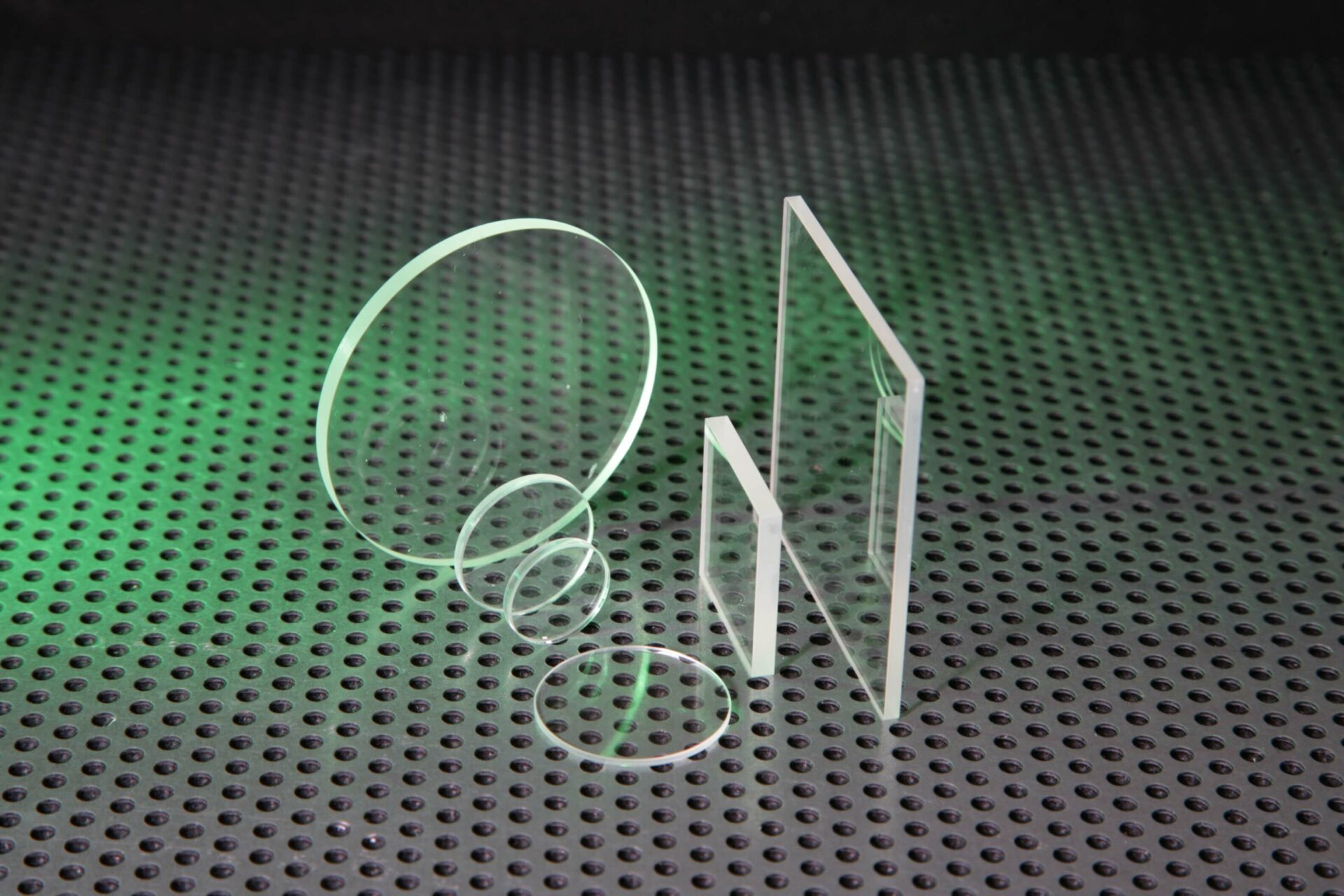

Optical windows and plates in sapphire substrate can be supplied in a range of standard shapes and sizes as well as custom designs.

Applications and uses of sapphire windows and plates

The strength, durability and precision offered by sapphire windows and plates make them an ideal choice for a wide range of applications for specialist industries and research which detect visible, ultra-violet and infra-red light

- Pressure windows, sight windows for industrial furnaces and viewing ports for engineering applications

- High precision scientific research tools

- Lenses and windows used for detection, inspection and exploration in the oil and gas sectors

- As a protective measure for cameras, sensors and lasers in military settings, particularly when the equipment in question needs to cope with extreme conditions. These conditions might apply on the ground, in the air or in and under water.

- In the medical sector sapphire windows and plates can play a role in a wide range of applications, from hair removal lasers and pharmaceutical monitoring to endoscopes and skin contact windows.

Sapphire windows and plates are particularly suited to high pressure environments, and so are ideal for use in cameras or lasers which have to operate with maximum efficiency in deep sea locations or high vacuum chambers.

The material properties of sapphire windows and plates

- Material transmission –a measure of the amount of light which passes through the optical window or plate.

- Refractive index – the degree to which the path of light passing through the window or plate is altered.

- Substrate hardness – sapphire is an extremely hard substrate. The surface hardness impacts on the durability and longevity of the finished application.

- Scattering or diffusion requirements – whether the window or plate will need to diffuse and scatter the light which is passing through the window or plate, as is required for particular scientific applications.

- Environmental durability and resistance – optical windows and plates are often placed in highly demanding environments. One of the properties which will determine the material used for a specific window or plate will be the ability of that material to withstand environmental factors such as extreme temperatures, pressure and the presence of corrosive substances. Sapphire is an ideal substrate choice for this purpose.

Properties of sapphire as an optical windows and plates substrate

The fact that sapphire is the hardest oxide material in existence and one of the hardest crystals – second only to diamond – means that it is extremely resistant to scratching no matter what kind of environment it is placed into.

This strength also means that sapphire optical windows and plates can be manufactured too much finer tolerances and thicknesses than other options, whilst still being highly resistant to factors such as pressure, temperature, thermal load and corrosion.

Sapphire substrate properties include the following:

- Transmission range from 0.2 – 5.5μm. (200nm to 5500nm), covering the UV, visible and near IR spectrum of light

- Excellent conductivity even at low temperatures

- Effective up to temperatures of 2,030 degrees Celsius

- Resistance to aggressive acids and alkalis up to temperatures of 1,000 degrees Celsius

- Total resistance to hydration and weathering

- High resistance to corrosion and abrasion

- High levels of electrical resistance

- Impervious to impact of surrounding chemicals except for particular extremely hot caustic substances

Examples of sapphire windows and plates

Random orientation

Sapphire used to make these plates and windows is cut to a random optical axis, while for higher optical applications ‘C’ cut Sapphire windows, ‘Z’ cut or 0° plane cut may be preferable. These windows can also be provided as UV coated or fluorescence free, and boast the many properties of sapphire detailed above.

They are used widely across scientific and industrial sectors, from highly calibrated sensors to viewing ports in extremely harsh environments. Sapphire windows and plates of this kind can generally be ordered from stock or custom made for specific requirements.

AR coated one side or both sides

Optical AR coatings can be applied to one or both sides of optical windows or plates can improve transmission properties as follows:

- UV 250nm-400nm

- Visible range 400nm-700nm

- IR 700nm-1100nm

Alternatives also include AR mid infrared coatings between 750nm-1550nm and 2-5 microns and single wavelength ‘V’ coatings. AR coated sapphire windows and plates are frequently used cameras and lasers and can be ordered from stock or custom made to meet specific requirements.

Cut to ‘C’ axis

Windows or plates cut to the ‘C’ axis i.e. to the optical axis perpendicular to the plane of the sapphire substrate is also referred to as ‘Z’ cut or 0° plane cut.

It offers all of the advantages of sapphire cut to a random orientation, with the added benefit of minimising the moderate birefringence present in sapphire cut to a random axis. ‘C’ cut sapphire windows and plates are particularly effective in camera systems, medical instruments and optical equipment, and can be ordered from stock or custom made with the option of including AR coatings on one or both sides.

Next Steps

To find out more about Sapphire Windows and Plates from UQG Optics, or any of our other optical products call us on 01223 420329 or email our sales team at info@uqgoptics.com