Anti-reflective (AR) optical coatings are a game-changer in improving the performance of optical devices. From reducing annoying glare to enhancing the precision of scientific instruments, AR coatings are a vital component in many technologies.

But what exactly are they and why are they so important? Let’s dive in.

What Are Anti-Reflective Optical Coatings?

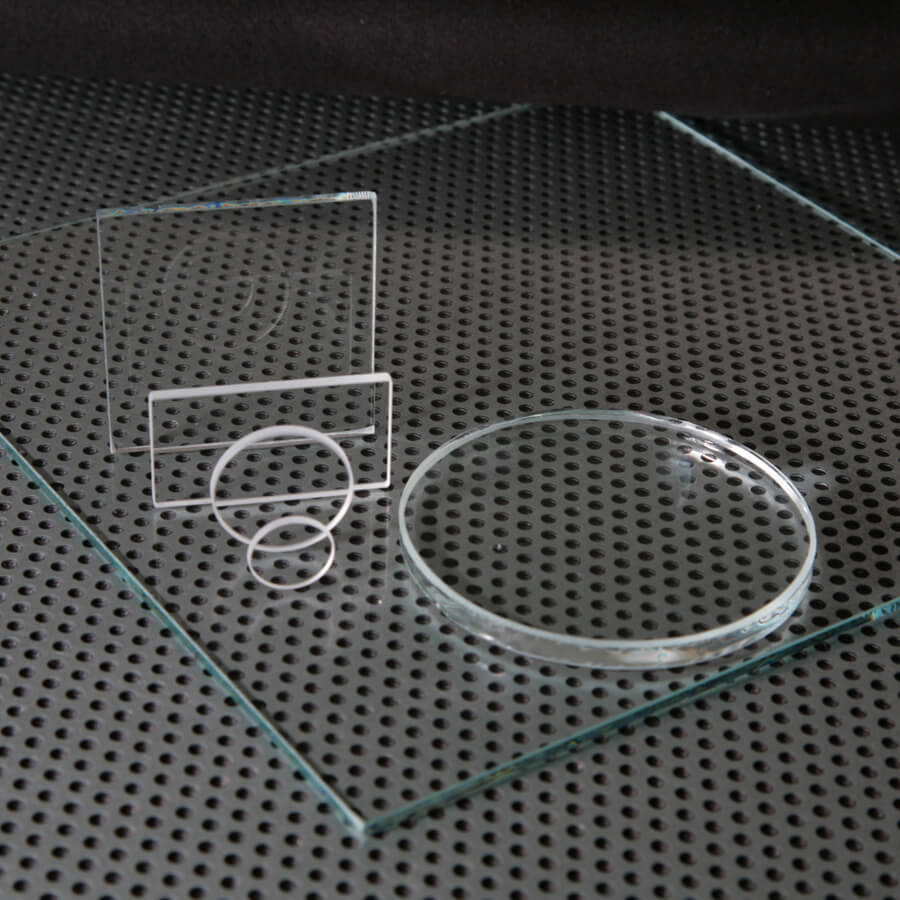

AR coatings are thin, multi-layered films applied to the surface of optical components such as lenses, windows and filters. Their purpose is to reduce reflections by interfering with light waves in a way that cancels out reflection. The result is more light passing through the optical element, enhancing both efficiency and clarity.

These coatings are designed to target specific wavelengths, ensuring minimal reflection for visible, ultraviolet, or infrared light, depending on the application. Common materials include magnesium fluoride and advanced dielectric compounds, tailored to meet the unique needs of each optical system.

The Key Benefits of AR Optical Coatings

Improved Light Transmission

When light hits an uncoated optical surface, around 4% is reflected off each side. In a complex system with multiple surfaces, this can result in significant light loss. AR coatings can reduce reflections to as low as 0.2%, allowing over 99% of light to pass through. This is particularly crucial for applications like:

Reduced Glare

Glare isn’t just annoying; it can hinder performance in critical applications. AR coatings minimise glare, improving visibility and reduce strain. This is especially beneficial in:

Enhanced Image Clarity

Reflections don’t just waste light—they create ghost images and stray light, which degrade image quality. AR coatings solve this issue by eliminating unwanted reflections. Applications include:

- Medical Imaging: Endoscopes and other imaging tools provide clear visuals for accurate diagnoses.

- Consumer Photography: Eliminating lens flare ensures sharper, professional-quality photos.

- Aerospace Optics: Precision is critical in environments like outer space, where stray reflections could compromise functionality.

Durability and Longevity

Modern AR coatings don’t just enhance optics—they also protect them. Many coatings include layers designed to resist scratches, repel water and endure extreme conditions. This makes them ideal for:

- Military and Aerospace Applications: Durable coatings withstand harsh environments, ensuring reliability.

- Consumer Products: From eyewear to cameras, scratch-resistant coatings extend the life of everyday items.

Aesthetic and Practical Appeal

Ever notice how premium lenses or high-end displays seem almost invisible? That’s AR coatings at work. By minimising reflections, these coatings make products look sleek and high-tech—an important selling point in competitive markets.

Applications of AR Optical Coatings

Anti-reflective coatings are integral to countless industries, enhancing the performance and efficiency of technologies we rely on daily. In consumer devices, such as smartphones, televisions and virtual reality headsets, they reduce glare and improve display clarity, making screens more vibrant and easier on the eyes.

Healthcare professionals depend on these coatings for precision in medical imaging equipment, ensuring clear visuals for accurate diagnostics and surgical procedures. In scientific research, AR coatings maximise light transmission and accuracy in instruments like microscopes and spectrometers, while the energy sector benefits from their ability to improve solar panel efficiency and optimise lighting systems.

Defence and aerospace industries utilise AR coatings to ensure reliability in extreme conditions, from fighter jet optics to satellite cameras and telecommunications rely on them to boost the performance of fibre optic networks. Whether improving consumer experiences or driving technological breakthroughs, AR coatings are a cornerstone of modern innovation.

Challenges and Considerations

While anti-reflective coatings offer significant benefits, they come with challenges that must be considered. High-quality AR coatings can be costly, particularly for specialised applications requiring customised designs or materials. Selecting the appropriate coating for specific wavelengths or environmental conditions requires expertise, as the wrong choice can compromise performance.

Although many AR coatings are durable, they can still be damaged by improper cleaning or harsh environmental factors, reducing their effectiveness over time. These considerations highlight the importance of proper care, maintenance and consultation with optical experts to ensure the coating meets the demands of its intended application.

Final thoughts

Anti-reflective optical coatings aren’t just about reducing reflections, they’re about enhancing performance, efficiency and durability across countless industries. These coatings play a vital role in modern technology. By understanding their benefits and applications, businesses and consumers alike can make informed decisions to maximise the value of their optical systems.

Speak with our experts today to find the right coating solutions for your specific needs. Call us now at +44 (0) 1223 420329 or Contact Us to get started.