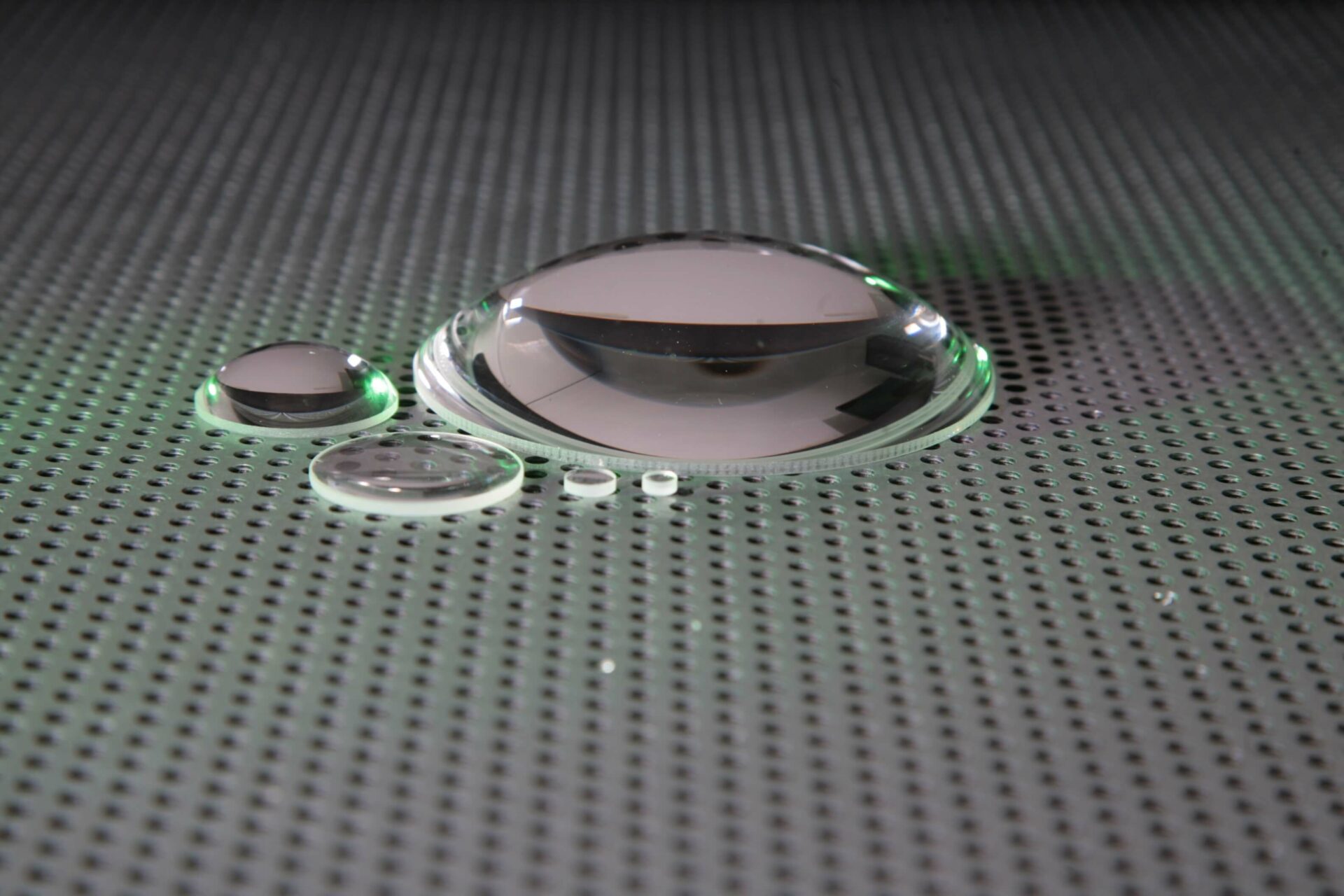

Optical lenses are designed and crafted with the aim of being able to focus or diverge light. An optical lens is an optically transparent device which utilises the focus or divergence of light to create a highly specific optical outcome. An optical lens might consist of a single element or multiple elements working together.

In general terms a Plano-Convex or Double-Convex lens enables a light source to be focused to a point, whereas Plano-Concave and Double-Concave lenses cause the light which passes through them to diverge.

Industries that use optical lenses

Any industry which relies on extremely accurate imaging is likely to make use of optical lenses of various types in a range of applications. From the scanners on a self-service till at the supermarket to microscopy in life sciences and sectors such as traffic control, imaging, medicine and defence, optical lenses can play a part in gathering images and recording highly accurate information.

The material properties of optical lenses

The specifications needed for a particular optical lens determines the choice of materials used for manufacturing. The properties and criteria of those materials will include the following:

- Refractive Index – a measure of the degree to which light slows down when it passes through a lens, which impacts on the angle at which the light is refracted.

- Dispersion – too much dispersion results in chromatic aberration, which degrades the quality of any image.

- Thermal Expansion Coefficient – a measure of the degree to which the surrounding temperature can change the performance of a lens. This property needs to be considered when an optical lens will be part of a system which is based in an outdoor setting with a variable temperature profile.

- Density – the density of an individual lens will impact on the weight of a system comprising multiple single lenses.

- Hardness – the hardness of the material used will impact on the fabrication process, which in turn will affect the cost of the finished system and its operational longevity. It will also need to be considered when the finished system is operating or being cleaned.

- Elasticity – the elasticity of a material will impact on the degree to which the lens in question can withstand high pressure environments, such as when being operated in a vacuum chamber.

Materials used in optical lens manufacturing

Optical lenses can be manufactured from a range of materials, with the choice dictated by the required properties as outlined above. The most popular materials include:

- Fused Quartz

- Fused Silica

- Optical glasses

- UV and IR crystals

- Optically moulded plastic

Popular Optical Lenses from UQG Optics

The Optical Lenses supplied by UQG Optics can be supplied from standard range stock or custom made from any of the materials listed above. We supply optical lenses which work across the UV to IR spectrums and can be used in commercial or high precision applications. Some of the most popular options include:

- BK7 Plano Convex & Bi-Vex Lenses

- Calcium Fluoride (CaF2) Lenses

- Fused Silica Lenses – Plano Convex & Bi-Convex

- Plastic Lenses

BK7 Plano Convex & Bi-Vex Lenses

BK7 Plano convex and bi vex lenses offer an all-purpose solution for focusing requirements. They are supplied either with one spherical surface and one flat surface or a bi-vex surface. They offer high quality optical results and superior surface quality. Optical Lenses of this kind are used in imaging systems, lasers and detectors, and can be supplied with single or multiple AR coatings to deal with multiple wavelengths. Costs of OEM optical lenses production can be controlled by opting for low-cost grades over precision quality.

Calcium Fluoride (CaF2) Lenses

CaF2 lenses offer an extremely high tolerance to laser damage, which makes them the ideal solution for laser applications. The lenses can be supplied in UV/IR and UV Monocrystalline and Polycrystalline which means they are suited to working in the infrared and ultraviolet spectral ranges. The robust nature of Calcium Fluoride means that it can withstand long term exposure to normal atmospheric conditions, and the lenses can be supplied with AR coatings for UV and IR wavelengths. We supply sizes ranging from 5mm to 100mm.

Fused Silica Lenses – Plano Convex & Bi-Convex

Fused Silica lenses are popular for applications operating in a deep ultra-violet spectral range. Lenses manufactured from Fused Silica have a lower coefficient of thermal expansion, which makes them the ideal choice for laser applications or those which operate in harsher environmental conditions. They are also a popular choice for medial fluorescence applications due to their low fluorescence, and UQG Optics provide coating options and lens diameters up to 300mm.

Plastic Lenses

Although they are not as robust as glass lenses, plastic lenses offer a cheaper and lighter alternative made from materials including Acrylic, Polycarbonate or Zeonnex (COC). Despite the cost saving, plastic lenses provide excellent optical properties including high transparency, low birefringence, low water absorption and excellent optical stability after heat and humidity exposure. They are used in a wide range of applications including military night vision goggles and can be supplied in a range of custom sizes and with varied coating options.

Next Steps

To find out more about Optical Lenses from UQG Optics, or any of our other optical products contact us on 01223 420329 or email our sales team at info@uqgoptics.com