This month in our product FAQ we are focusing on optical mirrors. These are popular products at UQG Optics, and we wanted to answer some of the questions we get asked a lot.

If your question is not reflected here (sorry for the pun, couldn’t resist!) please feel free to reach out to our friendly sales team who will be more than happy to help.

What are optical mirrors?

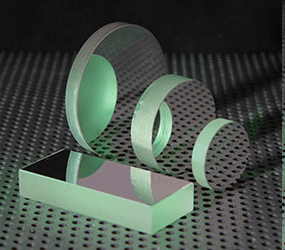

Optical mirrors are a key component of many forms of laboratory and scientific instrumentation. They are designed to reflect light in different ways in a range of applications including beam steering, interferometry, imaging and illumination. Optical mirrors are used in instrumentation across many such as astronomy, metrology and the solar energy industry, as well as laboratory research.

What kinds of optical mirrors do UQG Optics supply?

We supply 5 different kinds of optical mirror. Colour separating mirrors, concave mirrors, flat optical mirrors, front surface mirrors and plate beam splitters.

Do optical mirrors come in a range of materials?

The material used to manufacture optical mirrors range from general optical glasses to low expansion glass.

Materials for optical mirrors include borosilicate glass, fused silica and optical crown glass. Due to fused silica’s low coefficient of thermal expansion it is commonly used in optical mirrors where environmental conditions may vary. Optical mirrors may also be manufactured from Pyrex and Zerodur.

What specifications can optical mirrors have?

Optical Mirrors can be made to suit different requirements of reflectivity, dispersion, flatness and coating durability. Specifications include diameter, radius of curvature, thickness, focal length and surface finish.

What materials can optical mirrors be coated in?

UQG Optics supplies optical mirrors treated with large range of reflective optical coating materials such as aluminium, silver, gold and dielectric coatings.

The choice of coating material for optical mirrors depends on the degree of reflectivity required and the wavelength or wavelength range. Metal substrate optical mirrors are usually used when the coefficient of thermal expansion must remain constant between mirror and mount.

What kind of coatings can UQG Optics supply?

UQG Optics supplies the following kinds of coatings for different types of mirror requirement:

- Metallic coatings: good for reflectivity over a wide spectral region, but may be prone to damage

- Dielectric coatings: offer higher reflectivity over several spectral ranges

- Ultrafast coatings: ideal for applications needing steering ultrashort pulses and dispersive effect

Is it possible to enhance the effective properties of optical mirrors?

Yes, optical mirrors manufactured from low expansion glasses such as borosilicate, float glass, BK7 Fused Silica and Zerodur can be enhanced to offer greater reflective properties by coating with dielectric materials with high precision optical coatings.

What are the properties of concave surface optical mirrors?

Optical mirrors with concave surface are ideal for light focusing applications.

What are the properties of convex surface optical mirrors?

Convex optical mirrors curve inward away from the incident light and are ideal for increasing the imaging system field of view.

Next steps

Ask a UQG Optics sales specialist any question about optical mirrors or any other optical component requirements. Call us on 01223 420329 or email info@uqgoptics.com